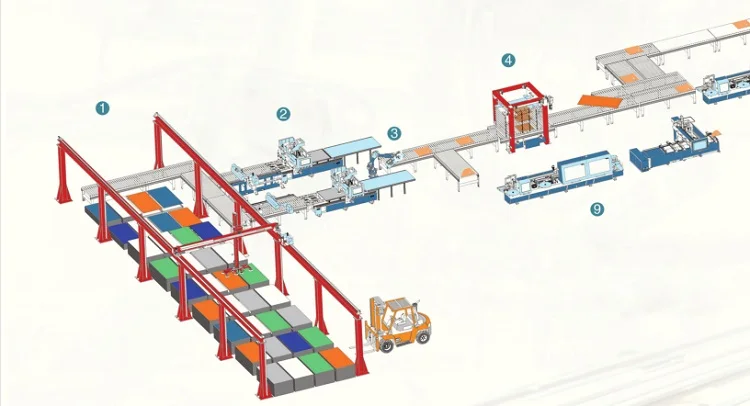

This Panel Furniture Smart Factory production line integrates advanced CNC routers, robotic handling, and automated warehousing to deliver intelligent, unmanned manufacturing for cabinet wardrobe doors and other furniture. It supports flexible configurations, increases automation, reduces labor dependency, and enhances production efficiency. The system is suited for processing wood panels, solid wood furniture, acrylics, PVC, and non-metal materials with precision. Equipped with CE certification, it ensures compliance with EU safety standards, providing market access and long-term reliability.

Professionally promote the informationization, intelligence and unmanned construction of the furniture industry. The combination is flexible, the process is changeable, and an automated production mode that meets the needs of the customer’s entire plant is created. Combine robots with intelligent automation equipment to improve the automation level of the factory, get rid of the dependence on workers, and effectively improve management efficiency and production efficiency.We strive to make your production smarter, faster and more cost-feeicient with minimum human labor required.

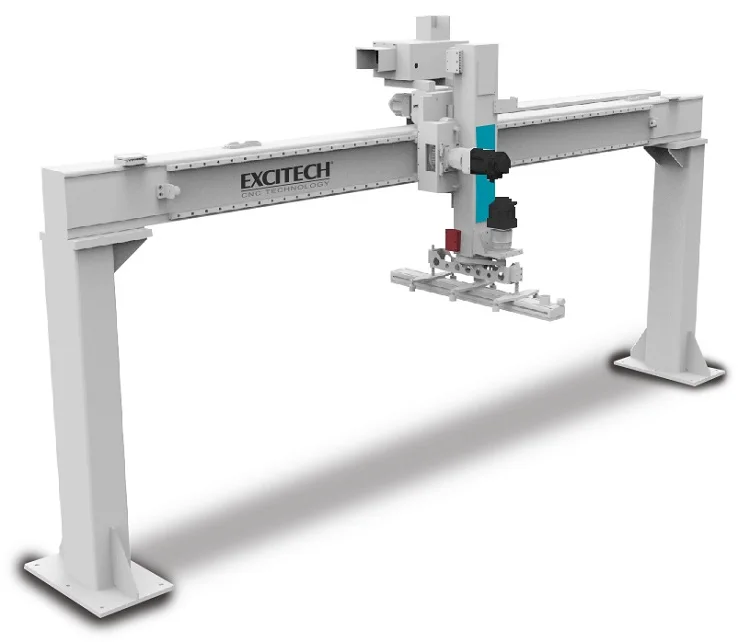

1. Automatic Warehouse

Gantry structure Panel transporter can automatically pick the wood panel from the warehouse.

2. Nested-based CNC with Pre-labeling

It is mainly for wood panel drilling and grooving.

3. Robot

Robot automatically puts the semi-finished product on the conveying roller table for subsequent operation.

4. Tempory Parts Storage

Semi-finished products can be temporarily stored in the cache bin.

5. Return Conveyors

6. Five-Sided Drilling Machine

7. Six-sided Drilling Machine

8. Sorting and Packing

9. Edgebanding and Drilling for Small/ Irregular-shaped Parts

WhatsApp us