Highly Flexible All Rounder Edgebanding Machine designed for high-end whole house customization, featuring a feed speed of 26-30m min and precise servo gluing to reduce glue lines. Equipped with TECO PLC and inverter, it ensures reliable performance. The machine supports edge thickness of 0.4-3mm and workpiece dimensions starting at 60*120mm. With a 1-year warranty on core components like the motor, pump, and gearbox, it guarantees long-term reliability. CE certified, ensuring compliance with EU safety standards and enabling market access.

High speed flexible edge banding machine for high-end whole house customization.

| Description | EF687 | ||

| Workpiece length | Min.120mm | Input voltage | 380v |

| Working piece width | Min.60mm | Input frequency | 50HZ |

| Workpiece thickness | 9~80mm | Output frequency | 200HZ |

| Edge thickness | 0.4~3mm | Power | 22kw |

| Feed speed | 20~30m/min | Machine size | 9580*1800*940mm |

| Minimum Workpiece Dimension | 60*120 | Pre-milling tool | Φ100*H65mm*Φ 30 diamond tool |

1.Horizontal End Trimming

Closed-loop control, no chipping.

Reliable structure and convenient maintenance.

2. Servo gluing

Servo motor controls the amount of glue precisely, reduce glue lines and avoid glue leakage.

The interiror of the glue pot is clean and smooth, and it’s eary to clean up the remaining glue.

3. Gluing with quick-melt

The gluing unit features quick melt , reducing the thawing time of glue and guaranteeing perfect glue quality on different edge materials.

4. Corner Trimming

It is equipped with 4 motors and works well with various edge thickness and invariably result in perfect round corner.

Servo controlled corner trimming function

5. R scraping

No power scraping mechanism, for PVC/ABS edge banding within 3mm, R scraping edge is to remove the edge of the finishing unit in the processing edge band, so that the edge of the edge band More full and straight.

6. Flat scraping

Pneumatic control, the role is to scrape off the remaining glue left on the wood, reducing the glue line.

Application:

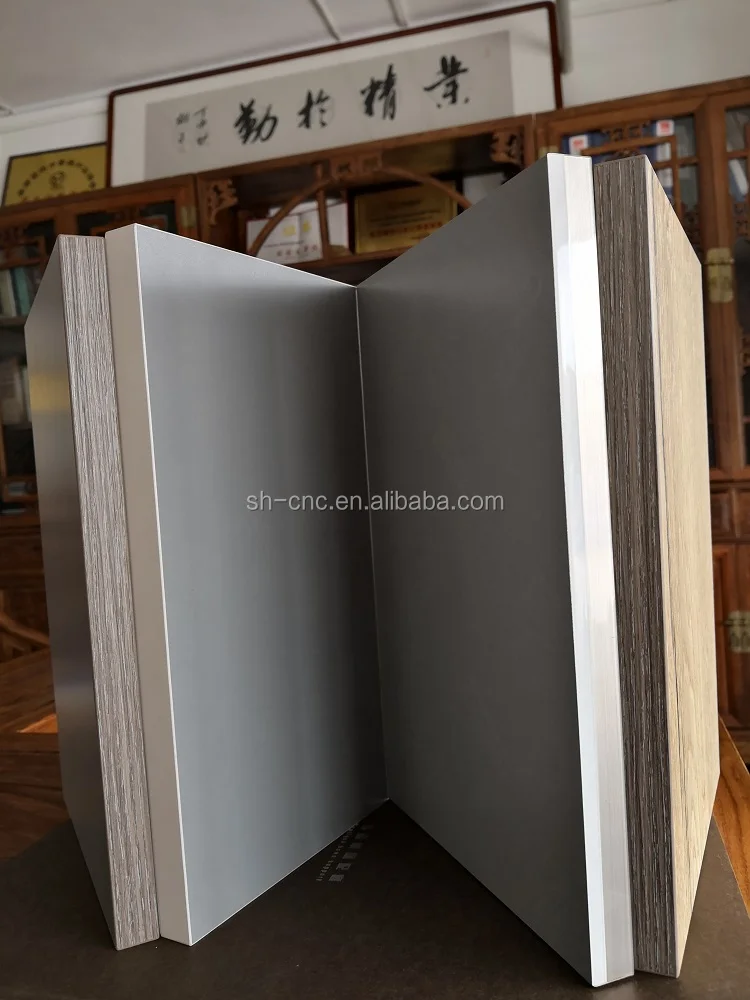

The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips.

WhatsApp us