The Heavy Duty PVC Edge Banding Machine EF681 is designed for high-precision, automated edge sealing in panel furniture manufacturing. It features advanced components like a Delta (Taiwan) inverter and PLC, AUTONICS temperature control, and TAIWAN AirTAC pneumatic parts. With functions like pre-milling, corner trimming, and flat scraping, it ensures aesthetic, waterproof, and durable edge banding. Suitable for PVC, polyester, melamine, and wood strips, it supports efficient large-scale production.

Edge banding work is an important process in the manufacture of panel furniture. The quality of the edge banding directly affects the quality, price and grade of the product. By edge banding, it can improve the appearance quality of the furniture, avoid the corners damage and the veneer layer pick up or peel off, and at the same time, it can play the role of waterproofing, close the release of harmful gases and reduce deformation during the transportation and useing process. The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips. The structure of the edge banding machine mainly includes the fuselage, various processing components and control systems. The processing components mainly include: pre-milling, infrared heating, gluing with quick-melt, rough trimming, fine trimming, corner trimming, scraping, off-cut, spray cleaning agent, buffing with air cyliner controlled. Mainly used for edge sealing of panel furniture. It is characterized by automation, high efficiency, high precision and aesthetics. It has been widely used in panel furniture manufacturers.

Model | EF686 |

Electric lifting | Maximum effective stroke=60mm |

Size | 9580*830*1678mm |

Power | 28kw |

Feeding speed | Close corner trimming =30m/Min. Open corner trimming =22m/Min |

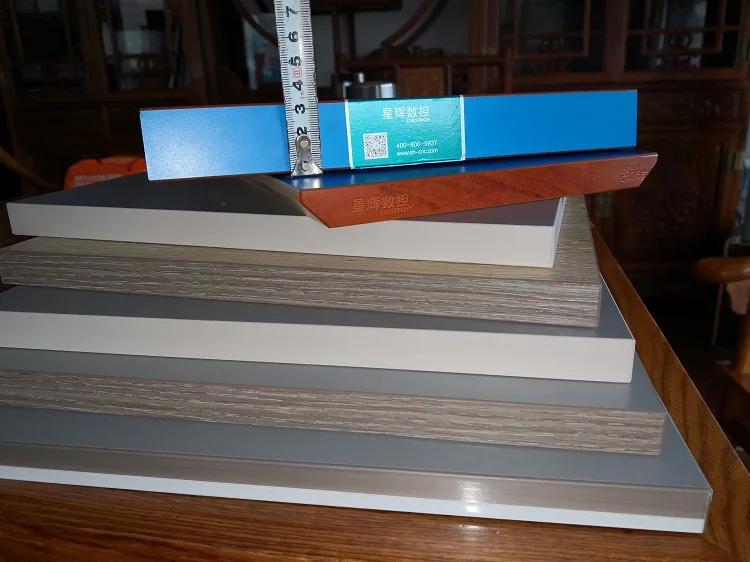

Work-piece thickness | 10-60mm |

Edge thickness | 0.4-3mm |

Edge width | 16-65mm |

Work-piece length | Close corner trimming >120mm. Open corner trimming >200mm |

Work-piece width | >60mm |

| Part’s name | Brand |

| Inverter | Delta( TAIWAN) |

| PLC | Delta( TAIWAN) |

| Human-machine interface | Delta( TAIWAN) |

| Temperature control module | AUTONICS (KOREA) |

| Air switch | DELIXI |

| AC contactor | SHIHLIN (TAIWAN) |

| Intermediate relay | Weidmuller (Germany) |

| Travel switch | America HONEYWELL |

| Switch button | German SIMENS |

| High-speed motor | CHANGLONG( custom) |

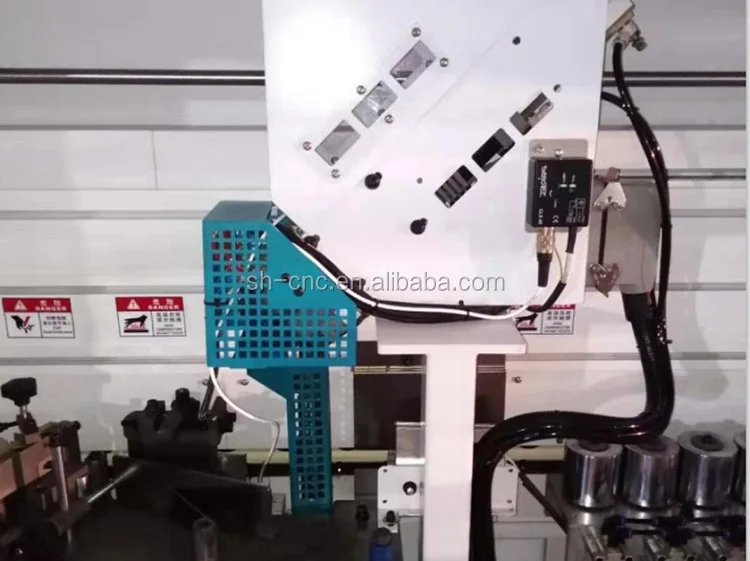

| Pneumatic components | TAIWAN AirTAC |

Functions:

Spray Release Agent→Pre Milling→Pre-heating→Hotmelt→Bottom Glue pot tape feeding and pressing→Top Glue pot tape feeding and pressing→Pneumatic Horizontal End Trimming→Rough Trimming→Fine Trimming→Corner Trimming with 2 motors→Scraping→Off Cut→Flat scraping→Spray Clean Agent→Buffing*2

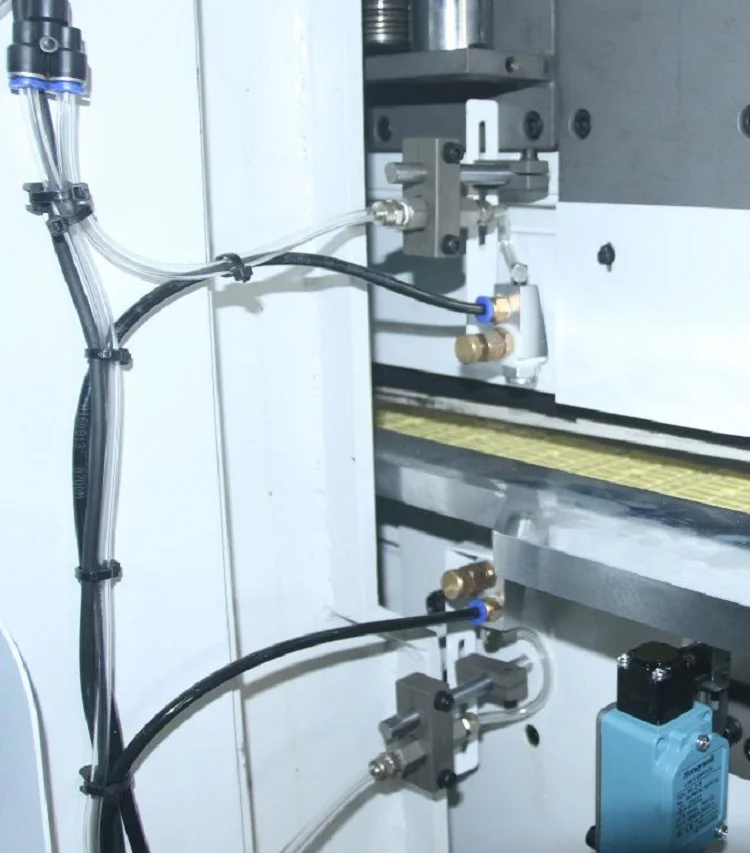

1.Spray realease agent

This device spray-applies a thin coat of release agent to the upper and lower edge area of the workpiece and prevents squeezed out glue from adhering to the workpiece.

2. Pre-milling unit

It is equipped with diamond tools for better cut and longer use. This device removes the burr or uneveness on the edge of the workpiece, leaving a smooth surface for the edgebanding. It can profile units available upon request.

3. Gluing with quick-melt

The gluing unit features quick melt , reducing the thawing time of glue and guaranteeing perfect glue quality on different edge materials.

4. Corner Trimming

It is equipped with 4 motors and works well with various edge thickness and invariably result in perfect round corner.

5. R scraping

No power scraping mechanism, for PVC/ABS edge banding within 3mm, R scraping edge is to remove the edge of the finishing unit in the processing edge band, so that the edge of the edge band More full and straight.

6. Flat scraping

Pneumatic control, the role is to scrape off the remaining glue left on the wood, reducing the glue line.

Application:

The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips.

WhatsApp us