Fully automated edge banding cell for plywood, designed to enhance furniture production with intelligence and unmanned operation. It reduces labor costs by eliminating the need for operators, increases efficiency by at least 25% compared to manual operation, and ensures smarter, cost-efficient production. The system combines an EV583 edgebander with advanced features like pre-milling, gluing, trimming, and buffing, supported by international brand components for long-term reliability. CE-certified, ensuring compliance with EU safety standards and enabling market access.

Professionally promote the informationization, intelligence and unmanned construction of the furniture industry. The combination is flexible, the process is changeable, and an automated production mode that meets the needs of the customer’s entire plant is created. Combine edgebanding machine with roller line to improve the automation level of the factory, get rid of the dependence on workers, and effectively improve management efficiency and production efficiency.We strive to make your production smarter, faster and more cost-feeicient with minimum human labor required.

Advantage:

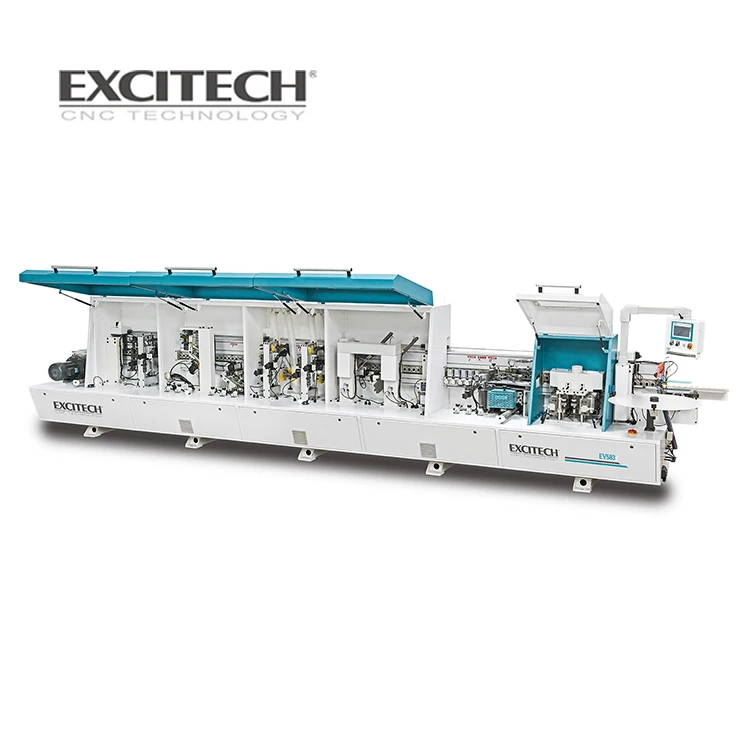

EV583 Edgebander

Pre milling,gluing,end trimming,rough trimming, fine trimming, corner trimming,scraping, off-cut, flat scraping and buffing.

| Description | EV583 | ||

| Working piece length | Min.150mm | Input voltage | 380v |

| Working piece width | Min.60mm | Input frequency | 50HZ |

| Panel thickness | 10~60mm | Output frequency | 200HZ |

| Edge width | 12~65mm | Power | 16.6kw |

| Edge thickness | 0.4~3mm | Air pressure | 0.6pa |

| Feed speed | 16~23m/min | Machine size | 7640*950*1608mm |

| Min. workpiece size | 300*80mm /150*150mm(L*W) | ||

| Part’s name | Brand |

| Inverter | Delta( TAIWAN) |

| PLC | Delta( TAIWAN) |

| Human-machine interface | Delta( TAIWAN) |

| Temperature control module | AUTONICS (KOREA) |

| Air switch | DELIXI |

| AC contactor | SHIHLIN (TAIWAN) |

| Intermediate relay | Weidmuller (Germany) |

| Travel switch | America HONEYWELL |

| Switch button | German SIMENS |

| High-speed motor for end trimming | CHANGLONG( custom) |

| Pneumatic components | TAIWAN AirTAC, Japan SMC |

Power Roller: 2000*1350mm+ 9000*1350mm

Air Table: 1500*1350mm + 1800*530mm

1. Edgebander

2. Power Roller line

The panel is transported by the power roller conveyor with high speed, improves transmission efficiency.

3. Bend Roller

The bend roller conveyor uses a cone roller as a carrier to smoothly transport articles along the curve. The bend roller conveyor is used in conjunction with the linear conveyor to achieve very good corner conveying. The cargo can maintain its relative position during the conveying process and realize synchronous conveying.

WhatsApp us