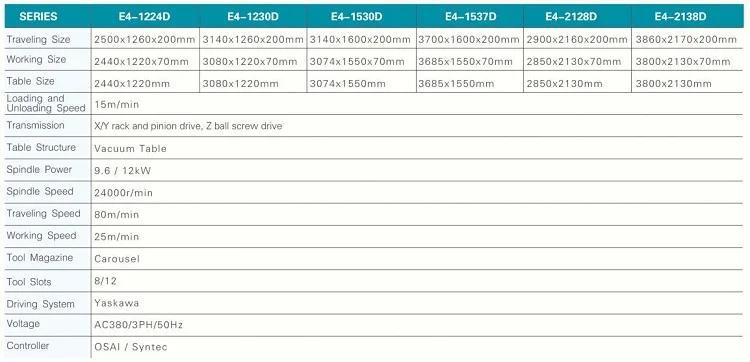

The Excitech E4-2138D CNC machining nesting line offers a fully automated solution for customized furniture production, featuring automatic loading and unloading systems with world-class components like an Italian HSD spindle, German helical rack, and Japanese linear guides. It supports versatile operations such as nesting, routing, drilling, and engraving in one machine. Equipped with CE certification, ensuring compliance with EU safety standards and enabling global market access.

Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time. World’s first class components–Italian high-frequency electro spindle, controller system and drill bank, German helical rack and pinion drives, Japanese self-lubricating and dust-proof square linear guides and high precision planetary gear reducers, etc.Truly versatile–nesting, routering, vertical drilling and engraving all in one. It is well-suited for panel furniture, office furniture, cabinets production.

Feature:

E4 Nested Based Prodution Flow

1. Carousel Tool changer

8 tools or more upon request.

Servo drives for faster and more accurate motion available.

2. HSD spindle with boring unit

HSD spindle: 9.6kw, higher power available upon request.

Italian drill bank:5+4 vertical drills

3. Auto loading and unloading system

Application:

Furniture:ideally suitable for processing cabinet door, wooden door, solid wood furniture, panel wood furniture, windows, tables and chairs, etc.

Other wooden products: stereo box, computer desk, musical instruments, etc.

Well-suited for processing panel, insulating materials, plastic, epoxy resin, carbon mixed compound, etc.

Decoration: acrylic, PVC, density board, artificial stone, organic glass, soft metals like aluminum and copper, etc.

WhatsApp us